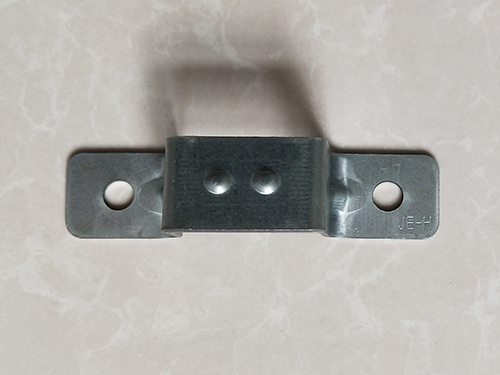

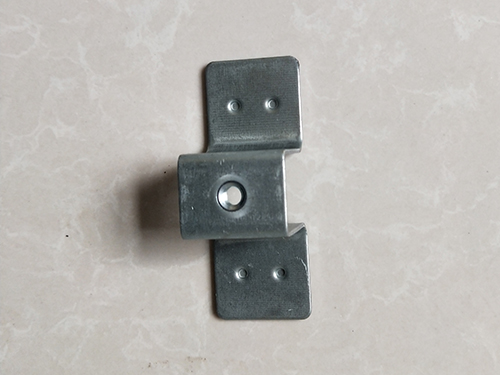

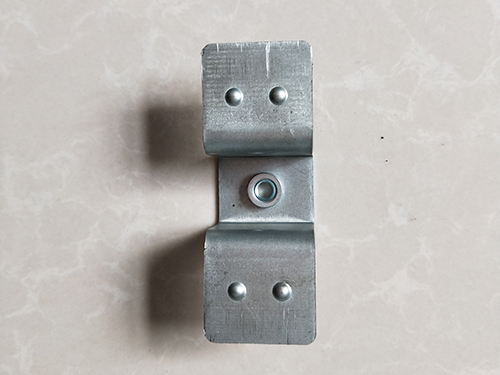

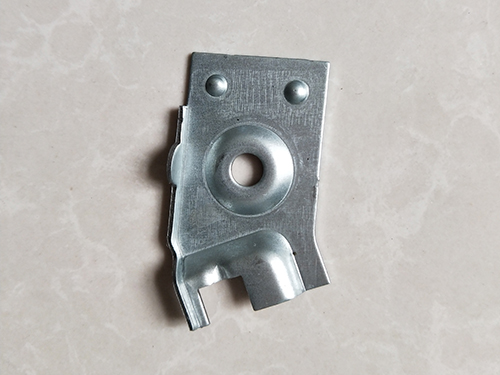

bracket

Attention should be paid to the following during the production of brackets:

During the stamping process of general workpieces, especially during cold forging and stamping, the temperature will quickly rise. If lubricating oil is added for lubrication, and stamping is carried out directly without lubrication, in addition to affecting the smoothness of the workpiece, the mold life will be shortened and the accuracy will be reduced. Therefore, a large amount of cost will be invested in improving the mold. It is precisely for this reason that stamping lubrication is necessary in cold forging and stamping.

In the case of producing dozens or hundreds of stamped parts per minute, completing processes such as feeding, stamping, discharging, and waste disposal in a short period of time often leads to personal, equipment, and quality accidents. Therefore, production in stamping is a very important issue. The stamping measures are:

① Realize mechanization and automation of material input and output.

② Set up mechanical protective devices to prevent hand injuries. Stamping parts should be equipped with mold protective covers, automatic material return devices, and manual tool feeding and unloading.

③ Set up electrical protection and power-off devices. Set up photoelectric or air curtain protection switches, dual or multiple hand series start switches, anti misoperation devices, etc.

④ Improve the clutch and brake structure, so that the crankshaft, connecting rod, and punch of the press can immediately stop in their original position after a danger signal is issued.

Glass lifter stamping parts series

Light Truck Blocker Series

New Energy Sheet Metal Parts Series

New energy vehicle parking bracket series

Dust collector series

Analysis and Application of Stamping Parts and Precautions for Mold Forging

Analysis and Application of Stamping Parts and Precautions for Mold ForgingTo deal with problems caused by materials, manufacturing personnel can choose appropriate p...

Key points of mold and tooling management for metal stamping equipment and mold

Key points of mold and tooling management for metal stamping equipment and moldRegular maintenance is implemented for tooling molds, and a mandatory pre repair system is ...

Factors affecting the management of production materials and defects in stamping

Factors affecting the management of production materials and defects in stampingStrengthen the control and supervision of incoming stamping parts. For the stamping worksho...

Modernization process upgrade and quality process monitoring management of metal

Modernization process upgrade and quality process monitoring management of metalThe manufacturing process level of chassis stamping parts in automobile production not only...

Quality improvement measures and reasonable selection of equipment for metal sta

Quality improvement measures and reasonable selection of equipment for metal staStamping technology can be divided into two categories: separation process and forming proc...