Body and chassis sheet metal stamping parts

Body and chassis sheet metal stamping parts are a type of stamping part. Stamping is a forming and processing method that uses a press and mold to apply external force to sheet, strip, pipe, and profile materials, causing them to undergo plastic deformation or separation, thereby obtaining the desired shape and size of the workpiece (stamping part). Stamping and forging belong to plastic processing (also known as pressure processing), collectively referred to as forging. The stamping blanks are mainly hot-rolled and cold-rolled steel plates and strips. 60-70% of the world's steel is sheet metal, with the majority being stamped into finished products. The body, chassis, fuel tank, radiator fins of automobiles, steam drum of boilers, shell of containers, iron core and silicon steel sheets of motors and electrical appliances are all stamped and processed. There are also a large number of stamped parts in products such as instruments, household appliances, bicycles, office machinery, and household utensils.

The mold used for stamping parts is called a stamping die, abbreviated as a punching die. A stamping die is a tool used to process materials (metal or non-metal) in batches into the required stamping parts. Stamping dies are crucial in stamping, and without qualified dies, mass stamping production becomes difficult; Without a punching die, the stamping process cannot be achieved. Stamping technology, molds, stamping equipment, and stamping materials constitute the three elements of stamping processing, and only by combining them can stamped parts be obtained.

Stamping processing is a production technology that utilizes the power of conventional or stamping equipment to directly deform the sheet metal in the mold, thereby obtaining the shape, size, and performance of product parts. Sheet metal, molds, and equipment are the three essential elements of stamping processing. According to the stamping processing temperature, it is divided into hot stamping and cold stamping. The former is suitable for processing sheet metal with high deformation resistance and poor plasticity; The latter is carried out at room temperature and is a commonly used stamping method for thin plates. It is one of the main methods of metal plastic processing (or pressure processing) and also belongs to material forming engineering technology.

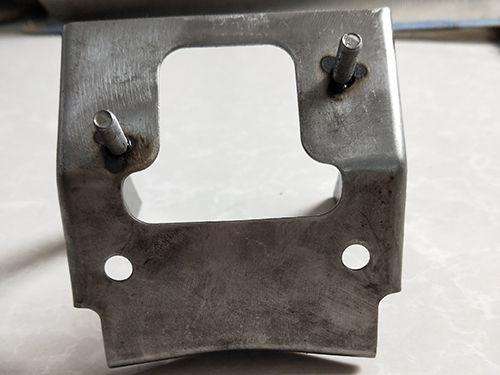

Glass lifter stamping parts series

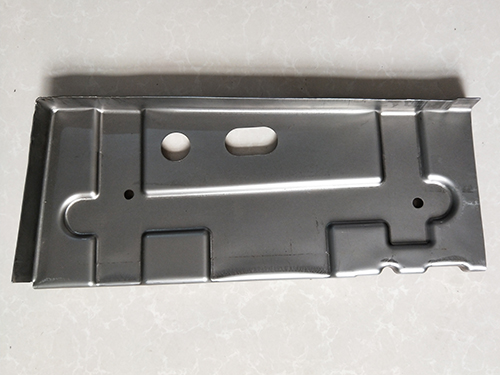

Light Truck Blocker Series

New Energy Sheet Metal Parts Series

New energy vehicle parking bracket series

Dust collector series

Analysis and Application of Stamping Parts and Precautions for Mold Forging

Analysis and Application of Stamping Parts and Precautions for Mold ForgingTo deal with problems caused by materials, manufacturing personnel can choose appropriate p...

Key points of mold and tooling management for metal stamping equipment and mold

Key points of mold and tooling management for metal stamping equipment and moldRegular maintenance is implemented for tooling molds, and a mandatory pre repair system is ...

Factors affecting the management of production materials and defects in stamping

Factors affecting the management of production materials and defects in stampingStrengthen the control and supervision of incoming stamping parts. For the stamping worksho...

Modernization process upgrade and quality process monitoring management of metal

Modernization process upgrade and quality process monitoring management of metalThe manufacturing process level of chassis stamping parts in automobile production not only...

Quality improvement measures and reasonable selection of equipment for metal sta

Quality improvement measures and reasonable selection of equipment for metal staStamping technology can be divided into two categories: separation process and forming proc...