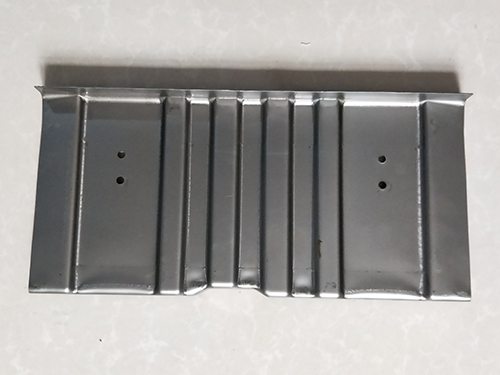

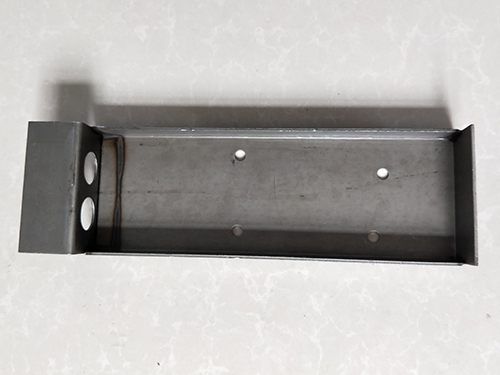

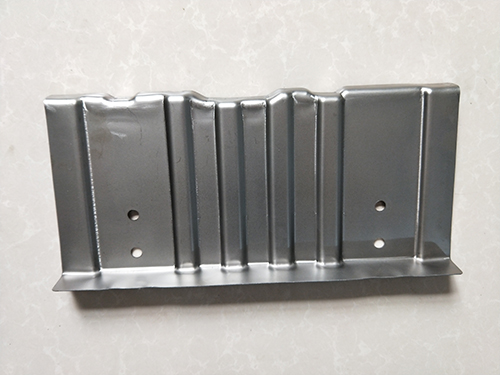

Stamping parts for battery box

Stamping parts for battery boxes are formed by applying external forces to plates, strips, pipes, and profiles using a press and mold, causing plastic deformation or separation to obtain the desired shape and size of the workpiece (stamping part). Stamping and forging belong to plastic processing (also known as pressure processing), collectively referred to as forging. The stamping blanks are mainly hot-rolled and cold-rolled steel plates and strips.

Design principles for stamping parts of battery box

The stamping parts designed meet the requirements of product usage and technical performance, and are easy to assemble and repair.

The stamping parts designed are conducive to improving the utilization rate of metal materials, reducing the variety and specifications of materials, and minimizing material consumption as much as possible. If possible, use inexpensive materials to achieve zero waste and minimal waste cutting of parts.

The designed stamping parts have a simple shape and reasonable structure, which is conducive to simplifying the mold structure and reducing the number of processes. That is, the entire part can be processed with fewer and simpler stamping processes, reducing the need for other methods of processing. It is also conducive to stamping operations, facilitating the organization to achieve mechanization and automation production, and improving labor productivity.

The stamping parts designed should have lower requirements for dimensional accuracy and surface roughness levels as much as possible under normal use, and be conducive to product interchangeability, reducing waste and ensuring stable product quality.

The stamping parts designed should be conducive to using existing equipment, process equipment, and process flow as much as possible for processing, and should also be conducive to extending the service life of the stamping die.

Glass lifter stamping parts series

Light Truck Blocker Series

New Energy Sheet Metal Parts Series

New energy vehicle parking bracket series

Dust collector series

Analysis and Application of Stamping Parts and Precautions for Mold Forging

Analysis and Application of Stamping Parts and Precautions for Mold ForgingTo deal with problems caused by materials, manufacturing personnel can choose appropriate p...

Key points of mold and tooling management for metal stamping equipment and mold

Key points of mold and tooling management for metal stamping equipment and moldRegular maintenance is implemented for tooling molds, and a mandatory pre repair system is ...

Factors affecting the management of production materials and defects in stamping

Factors affecting the management of production materials and defects in stampingStrengthen the control and supervision of incoming stamping parts. For the stamping worksho...

Modernization process upgrade and quality process monitoring management of metal

Modernization process upgrade and quality process monitoring management of metalThe manufacturing process level of chassis stamping parts in automobile production not only...

Quality improvement measures and reasonable selection of equipment for metal sta

Quality improvement measures and reasonable selection of equipment for metal staStamping technology can be divided into two categories: separation process and forming proc...